Métodos destacados para la protección de la madera

DOI:

https://doi.org/10.29298/rmcf.v15i84.1441Palabras clave:

Degradación de la madera, durabilidad, nanotecnología, preservación de la madera, tratamientos químicos, tratamientos térmicosResumen

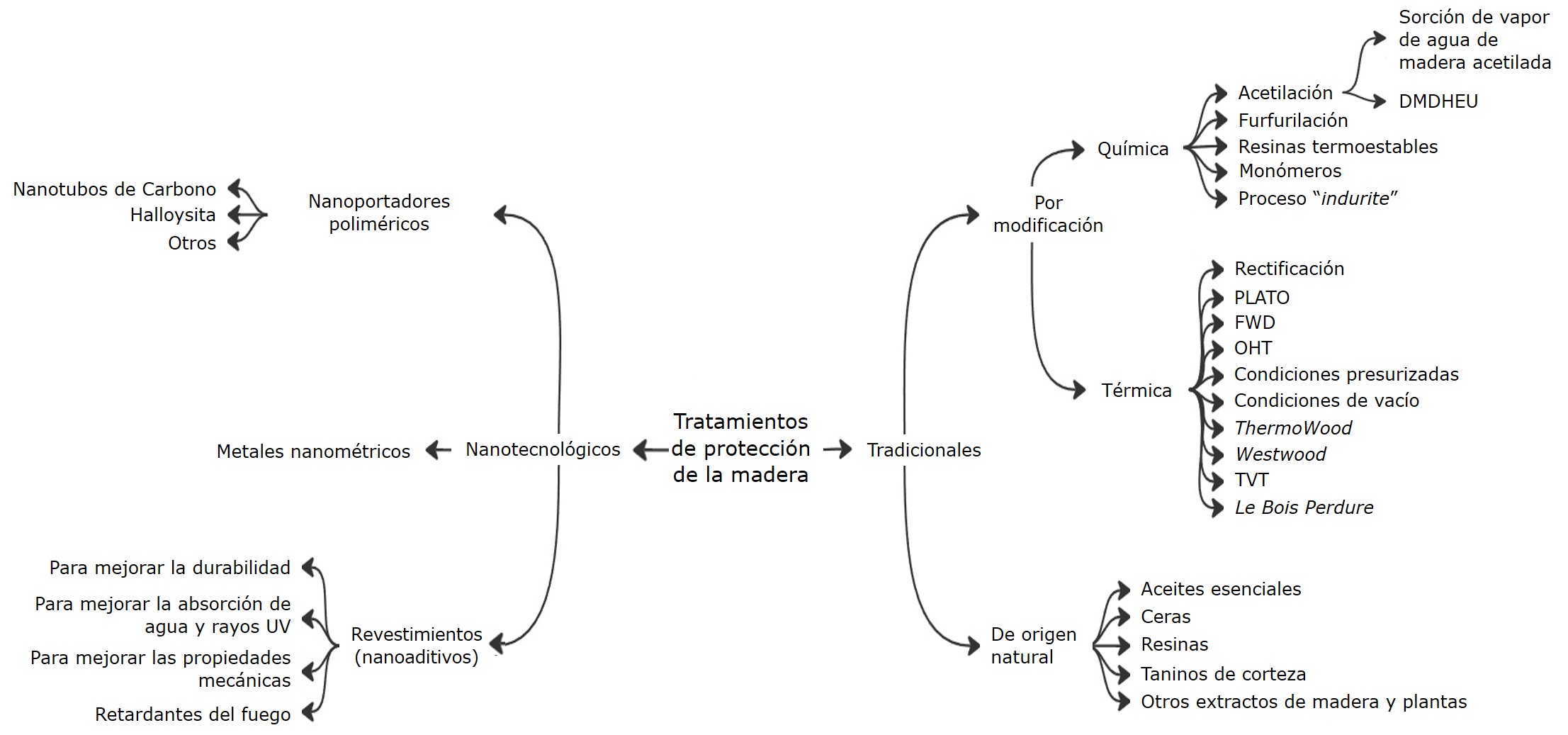

La madera es un material ampliamente usado en construcción, muebles, entre otras aplicaciones. Para mantener su calidad y durabilidad se emplean tecnologías de protección contra daños biológicos y los efectos del agua, la temperatura y la radiación que afectan sus propiedades físicas y mecánicas. En el presente trabajo se realizó una revisión de los tratamientos disponibles y se evaluaron sus ventajas e inconvenientes, además se definieron los criterios para su utilización. La temática se dividió en dos secciones: (I) los agentes degradadores de la madera, y (II) una clasificación de tecnologías de protección que incluyó tanto métodos tradicionales, como enfoques novedosos, tal es el caso de la nanotecnología. Bajo este enfoque, las conclusiones obtenidas apuntan a que diversos tratamientos químicos tradicionales reducen, sustancialmente, el daño biológico y la absorción de humedad en la madera. No obstante, deben considerarse los posibles efectos a la salud y al ambiente. Por otra parte, si se emplean tratamientos térmicos, la estabilidad dimensional de la madera mejora. El uso de compuestos nanométricos para la protección de la madera es una técnica muy prometedora y en creciente desarrollo. Sin embargo, es una tecnología de especial cuidado porque los nanomateriales tienen que ser tóxicos para los agentes causantes del biodeterioro, pero inocuos o menos peligrosos para los humanos y el ambiente.

Descargas

Citas

Acosta-Acosta, R., J. A. Montoya-Arango and E. Joma-da-Silva. 2021. Technologies applied to wood heat treatments, a review. Scientia et Technica 26(2):127-136. Doi: 10.22517/23447214.22641. DOI: https://doi.org/10.22517/23447214.22641

Asociación Española de Normalización. 2017. UNE-EN 350:2016 Durabilidad de la madera y de los productos derivados de la madera. Ensayos y clasificación de la resistencia a los agentes biológicos de la madera y de los productos derivados de la madera. Asociación Española de Normalización. Madrid, MD, España. 60 p.

Barua, S. K., P. Lehtonen and T. Pahkasalo. 2014. Plantation vision: Potentials, challenges and policy options for global industrial forest plantation development. International Forestry Review 16(2):117-127. Doi: 10.1505/146554814811724801. DOI: https://doi.org/10.1505/146554814811724801

Bi, W., H. Li, D. Hui, M. Gaff, … and M. Ashraf. 2021. Effects of chemical modification and nanotechnology on wood properties. Nanotechnology Reviews 10(1):978-1008. Doi: 10.1515/ntrev-2021-0065. DOI: https://doi.org/10.1515/ntrev-2021-0065

Broda, M. 2020. Natural compounds for wood protection against fungi—A review. Molecules 25(15):1-24. Doi: 10.3390/molecules25153538. DOI: https://doi.org/10.3390/molecules25153538

Candelier, K., M.-F. Thevenon, A. Petrissans, S. Dumarcay, P. Gerardin and M. Petrissans. 2016. Control of wood thermal treatment and its effects on decay resistance: a review. Annals of Forest Science 73:571-583. Doi: 10.1007/s13595-016-0541-x. DOI: https://doi.org/10.1007/s13595-016-0541-x

Cesprini, E., R. Baccini, T. Urso, M. Zanetti and G. Tondi. 2022. Quebracho-based wood preservatives: Effect of concentration and hardener on timber properties. Coatings 12(5):568. Doi: 10.3390/coatings12050568. DOI: https://doi.org/10.3390/coatings12050568

Chen, C., Y. Kuang, S. Zhu, I. Burgert, … and L. Hu. 2020. Structure–property–function relationships of natural and engineered wood. Nature Reviews Materials 5:642-666. Doi: 10.1038/s41578-020-0195-z. DOI: https://doi.org/10.1038/s41578-020-0195-z

De Avila D., R., R. Beltrame and D. A. Gatto. 2019. Discolouration of heat-treated fast-growing Eucalyptus wood exposed to natural weathering. Cellulose Chemistry and Technology 53(7-8):635-641. Doi: 10.35812/CelluloseChemTechnol.2019.53.62. DOI: https://doi.org/10.35812/CelluloseChemTechnol.2019.53.62

Dong, Y., Y. Qin, K. Wang, Y. Yan, … and S. Zhang. 2016. Assessment of the performance of furfurylated wood and acetylated wood: Comparison among four fast-growing wood species. BioResources 11(2):3679-3690. Doi: 10.15376/biores.11.2.3679-3690. DOI: https://doi.org/10.15376/biores.11.2.3679-3690

Ella N., L.-F., C. S. A. Bopenga B., F. E. Ngohang, L. E. Mengome, S. Aboughe A. and P. Edou E. 2022. Phytochemical and anti-termite efficiency study of Guibourtia tessmanii (harms). Léonard (Kévazingo) bark extracts from Gabon. Journal of the Korean Wood Science and Technology 50(2):113-125. Doi: 10.5658/WOOD.2022.50.2.113. DOI: https://doi.org/10.5658/WOOD.2022.50.2.113

Food and Agriculture Organization (FAO). 2022. Forestry Production and Trade. https://www.fao.org/faostat/en/#data/FO. (10 de abril de 2023).

Gérardin, P. 2016. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Annals of Forest Science 73:559-570. Doi: 10.1007/s13595-015-0531-4. DOI: https://doi.org/10.1007/s13595-015-0531-4

Goodell, B., J. E. Winandy and J. J. Morrell. 2020. Fungal degradation of wood: Emerging data, new insights and changing perceptions. Coatings 10(12):1-19. Doi: 10.3390/coatings10121210. DOI: https://doi.org/10.3390/coatings10121210

Gu, L., T. Ding and N. Jiang. 2019. Development of wood heat treatment research and industrialization. Journal of Forestry Engineering 4(4):1-11. Doi: 10.13360/j.issn.2096-1359.2019.04.001.

Hill, C., M. Altgen and L. Rautkari. 2021. Thermal modification of wood—a review: chemical changes and hygroscopicity. Journal of Materials Science 56:6581-6614. Doi: 10.1007/s10853-020-05722-z. DOI: https://doi.org/10.1007/s10853-020-05722-z

Jasmani, L., R. Rusli, T. Khadiran, R. Jalil and S. Adnan. 2020. Application of nanotechnology in wood-based products industry: A review. Nanoscale Research Letters 15:207. Doi: 10.1186/s11671-020-03438-2. DOI: https://doi.org/10.1186/s11671-020-03438-2

Jebrane, M., M. Pockrandt, I. Cuccui, O. Allegretti, E. Uetimane and N. Terziev. 2018. Comparative study of two softwood species industrially modified by Thermowood® and Thermo-Vacuum process. BioResources 13(1):715-728. Doi: 10.15376/biores.13.1.715-728. DOI: https://doi.org/10.15376/biores.13.1.715-728

Khademibami, L. and G. S. Bobadilha. 2022. Recent developments studies on wood protection research in academia: A review. Frontiers in Forests and Global Change 5:1-18. Doi: 10.3389/ffgc.2022.793177. DOI: https://doi.org/10.3389/ffgc.2022.793177

Lisuzzo, L., T. Hueckel, G. Cavallaro, S. Sacanna and G. Lazzara. 2021. Pickering emulsions based on wax and halloysite nanotubes: An ecofriendly protocol for the treatment of archeological woods. ACS Applied Materials & Interfaces 13(1):1651-1661. Doi: 10.1021/acsami.0c20443. DOI: https://doi.org/10.1021/acsami.0c20443

Mantanis, G. I. 2017. Chemical modification of wood by acetylation or furfurylation: A review of the present scaled-up technologies. BioResources 12(2):4478-4489. Doi: 10.15376/biores.12.2.4478-4489. DOI: https://doi.org/10.15376/biores.12.2.Mantanis

Marais, B. N., C. Brischke and H. Militz. 2022. Wood durability in terrestrial and aquatic environments–A review of biotic and abiotic influence factors. Wood Material Science & Engineering 17(2):82-105. Doi: 10.1080/17480272.2020.1779810. DOI: https://doi.org/10.1080/17480272.2020.1779810

Martha, R., M. Mubarok, I. Batubara, I. S. Rahayu, … and P. Gérardin. 2021. Effect of furfurylation treatment on technological properties of short rotation teak wood. Journal of Materials Research and Technology 12:1689-1699. Doi: 10.1016/j.jmrt.2021.03.092. DOI: https://doi.org/10.1016/j.jmrt.2021.03.092

Martínez-Abad, A., N. Giummarella, M. Lawoko and F. Vilaplana. 2018. Differences in extractability under subcritical water reveal interconnected hemicellulose and lignin recalcitrance in birch hardwoods. Green Chemistry 20(11):2534-2546. Doi: 10.1039/c8gc00385h. DOI: https://doi.org/10.1039/C8GC00385H

Martins, C., P. Santos and A. M. P. G. Dias. 2019. Portuguese hardwoods: an overview of its potential for construction purposes. In: van de Kuilen, J.-W. and W. Gard (Edits.). 7th International Scientific Conference on Hardwood Processing. Delft University of Technology. Delft, ZH, The Netherlands. pp. 286-294.

McKinley, P., A. Sinha and F. A. Kamke. 2019. Understanding the effect of weathering on adhesive bonds for wood composites using digital image correlation (DIC). Holzforschung: International Journal of the Biology, Chemistry, Physics, & Technology of Wood 73(2):155. Doi: 10.1515/hf-2018-0024. DOI: https://doi.org/10.1515/hf-2018-0024

Ormondroyd, G., M. Spear and S. Curling. 2015. Modified wood: review of efficacy and service life testing. Proceedings of the Institution of Civil Engineers-Construction Materials 168(4):187-203. Doi: 10.1680/coma.14.00072. DOI: https://doi.org/10.1680/coma.14.00072

Pacheco-Torgal, F., M. V. Diamanti, A. Nazari, C. G. Granqvist, A. Pruna and S. Amirkhanian (Edits.). 2019. Nanotechnology in eco-efficient Construction: Materials, processes and applications. Elsevier. Duxford, Cambs., United Kingdom. 876 p.

Papadopoulos, A. N., D. N. Bikiaris, A. C. Mitropoulos and G. Z. Kyzas. 2019. Nanomaterials and chemical modifications for enhanced key wood properties: A review. Nanomaterials 9:607. Doi: 10.3390/nano9040607. DOI: https://doi.org/10.3390/nano9040607

Peraza S., F. 2002. Protección preventiva de la madera. Asociación de Investigación Técnica de las Industrias de la Madera, AITIM. Madrid, Mad., España. 437 p.

Pockrandt, M., M. Jebrane, I. Cuccui, O. Allegretti, E. Uetimane and N. Terziev. 2018. Industrial Thermowood® and Termovuoto thermal modification of two hardwoods from Mozambique. Holzforschung: International Journal of the Biology, Chemistry, Physics, & Technology of Wood 72(8):701-709. Doi: 10.1515/hf-2017-0153. DOI: https://doi.org/10.1515/hf-2017-0153

Reinprecht, L. 2016. Wood deterioration, protection and maintenance. Wiley Blackwell. Oxford, Oxon, United Kingdom. 384 p. DOI: https://doi.org/10.1002/9781119106500

Rowell, R. M. 2020. Innovation in wood preservation. Polymers 12(7):1-7. Doi: 10.3390/polym12071511. DOI: https://doi.org/10.3390/polym12071511

Rust, M. K. and N.-Y. Su. 2012. Managing social insects of urban importance. Annual Review of Entomology 57:355-375. Doi: 10.1146/annurev-ento-120710-100634. DOI: https://doi.org/10.1146/annurev-ento-120710-100634

Sandberg, D., A. Kutnar and G. Mantanis. 2017. Wood modification technologies-a review. iForest-Biogeosciences and Forestry 10(6):895-908. Doi: 10.3832/ifor2380-010. DOI: https://doi.org/10.3832/ifor2380-010

Schardosin, F. Z., S. Nisgoski, P. H. G. Cademartori, S. R. Morrone and G. I. B. Muniz. 2020. Comparison of the effects of acetylation and paraffin emulsion impregnation in Pinus caribeae. Journal of Tropical Forest Science 32(3):237-245. Doi: 10.26525/jtfs2020.32.3.237. DOI: https://doi.org/10.26525/jtfs2020.32.3.237

Stefanowski, B. K., M. J. Spear and A. Pitman. 2018. Review of the use of PF and related resins for modification of solid wood. Timber 2018:165-179. https://research.bangor.ac.uk/portal/files/20769793/Stefanowski_Review.pdf. (15 de abril de 2023).

Tarmian, A., I. Z. Tajrishi, R. Oladi and D. Efhamisisi. 2020. Treatability of wood for pressure treatment processes: a literature review. European Journal of Wood and Wood Products 78(2):635-660. Doi: 10.1007/s00107-020-01541-w. DOI: https://doi.org/10.1007/s00107-020-01541-w

Teacă, C.-A., D. Roşu, F. Mustaţă, T. Rusu, … and C.-D. Varganici. 2019. Natural bio-based products for wood coating and protection against degradation: A review. BioResources 14(2):4873-4901. Doi: 10.15376/BIORES.14.2.TEACA. DOI: https://doi.org/10.15376/biores.14.2.Teaca

Teng, T.-J., M. N. M. Arip, K. Sudesh, A. Nemoikina, … and H.-L. Lee. 2018. Conventional technology and nanotechnology in wood preservation: A review. BioResources 13(4):9220-9252. Doi: 10.15376/biores.13.4.Teng. DOI: https://doi.org/10.15376/biores.13.4.Teng

Wang, D., Q. Ling, Y. Nie, Y. Zhang, … and F. Sun. 2021. In-situ cross-linking of waterborne epoxy resin inside wood for enhancing its dimensional stability, thermal stability, and decay resistance. ACS Applied Polymer Materials 3(12):6265-6273. Doi: 10.1021/acsapm.1c01070. DOI: https://doi.org/10.1021/acsapm.1c01070

Woźniak, M. 2022. Antifungal agents in wood protection—A review. Molecules 27(19):6392. Doi: 10.3390/molecules27196392. DOI: https://doi.org/10.3390/molecules27196392

Xie, Y., Q. Fu, Q. Wang, Z. Xiao and H. Militz. 2013. Effects of chemical modification on the mechanical properties of wood. European Journal of Wood and Wood Products 71:401-416. Doi: 10.1007/s00107-013-0693-4. DOI: https://doi.org/10.1007/s00107-013-0693-4

Xu, E., D. Wang and L. Lin. 2020. Chemical structure and mechanical properties of wood cell walls treated with acid and alkali solution. Forests 11:1-11. Doi: 10.3390/f11010087. DOI: https://doi.org/10.3390/f11010087

Yang, T., C. Mei, E. Ma and J. Cao. 2022. Effects of acetylation on moisture sorption of wood under cyclically changing conditions of relative humidity. European Journal of Wood and Wood Products 81(4):1-13. Doi: 10.1007/s00107-022-01903-6. DOI: https://doi.org/10.1007/s00107-022-01903-6

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2024 Revista Mexicana de Ciencias Forestales

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial 4.0.

Los autores que publiquen en la Revista Mexicana de Ciencias Forestales aceptan las siguientes condiciones:

De acuerdo con la legislación de derechos de autor, la Revista Mexicana de Ciencias Forestales reconoce y respeta el derecho moral de los autores, así como la titularidad del derecho patrimonial, el cual será cedido a la revista para su difusión en acceso abierto.

Todos los textos publicados por la Revista Mexicana de Ciencias Forestales –sin excepción– se distribuyen amparados bajo la licenciaCreative Commons 4.0 Atribución-No Comercial (CC BY-NC 4.0 Internacional), que permite a terceros utilizar lo publicado siempre que mencionen la autoría del trabajo y a la primera publicación en esta revista. (no permite el uso comercial)

Los autores pueden realizar otros acuerdos contractuales independientes y adicionales para la distribución no exclusiva de la versión del artículo publicado en la Revista Mexicana de Ciencias Forestales (por ejemplo, incluirlo en un repositorio institucional o darlo a conocer en otros medios en papel o electrónicos) siempre que indique clara y explícitamente que el trabajo se publicó por primera vez en la Revista Mexicana de Ciencias Forestales.

Para todo lo anterior, los autores deben remitir el formato de carta-cesión de la propiedad de los derechos de la primera publicación debidamente requisitado y firmado por los autores/as. Este formato debe ser remitido en archivo PDF al correo: editorial.forestal@inifap.gob.mx

Esta obra está bajo una licencia de Creative Commons Reconocimiento-No Comercial 4.0 Internacional.